Dispro – Distortion can be added as a value in the job style, or can be calculated using the built in tool provided by entering the cylinder information and plate details.

Seamless – Suitable for making Flexo and Gravure sleeves.

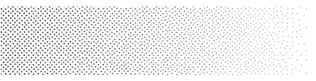

Lower Screen Limit – The smallest halftone dot size to be printed can be selected to avoid scum dots from being formed.

Powerful Viewer – The integrated viewer allows viewing of single separations, multiple colors or all colors of a job right down to pixel level. The Dot % viewer allows users to see the color mix on any part of the job.

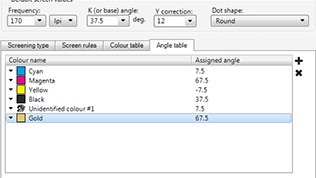

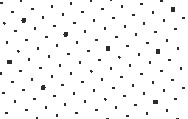

Multi Screening compatible – The RIP will manage multi screening inside a PS or PDF job. In addition the RIP allows setting to override the inherent screening, for example turning a part of the job set to 100LPI to FM screening.

Bearer Bars – Bearer bars can be added easily to jobs; these can be customised and be configured to user needs.

Device Support – StudioRIP drives all leading Flexo CTP machines but also can utilize Epson printers to create Flexo films.